I tried mounting the Screaming Banshee horn and haven't found a spot that worked well. The complete unit is too tall to fit any where except under the seat on the GIVI rack. I think that location feeds it too much mud and road-gross. Worth noting the horn is loud enough to work from under there. I tried it behind the head lamp as seen in the first photo. I used brackets to make more space behind the headlight. The pivot pushed the windscreen back and the headlight assembly was a little askew when closed up (longer brackets maybe). Doing this pointed the headlight the moon, I did not take the time to adjust the lamp back down so I can't be sure there is enough pivot to put the beam back on the roadway. Not awesome. Four brackets instead of two would fix the problems but I'm trying to be less invasive with the install.

Screaming banshee tucked behind the headlight assembly. Pushed beam too far up back to drawing board.

Screaming banshee tucked behind the headlight assembly. Pushed beam too far up back to drawing board. by

Ethestral, on Flickr

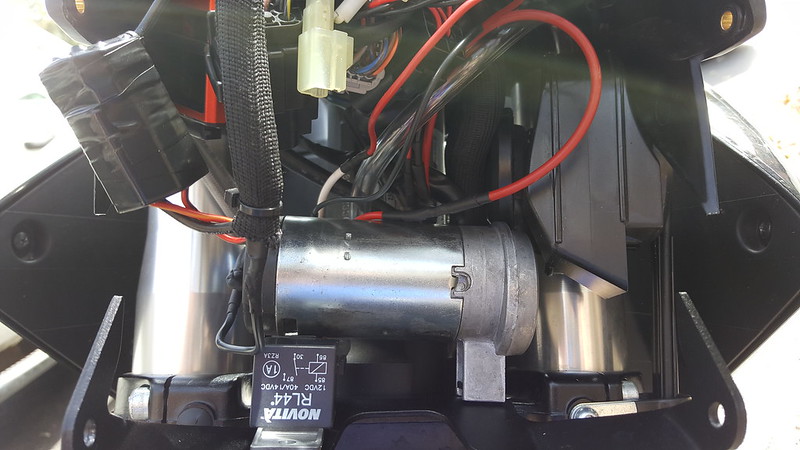

Figured I would mount some old broken stuff and see if it worked. Used a Stebel Nautilus, snapped at the clip that holds the horn onto the compressor (happens when you run them on a dual sport in the winter). The pieces still work but you have to zip tie them together to get blast that still sounds wheezy or silent depending on your tie skills. By separating them I was able to fit everything without changing the nose of the DSR. The horn portion and almost perfectly snaps around the fork tube. Then I set to work mounting the compressor nearby. I used some clear plastic tubing (3/8" outside diameter, 1/4" ID) and silicone to join the two parts. The shorter you keep the plastic tubing, the faster the horn sounds and sharper the initial blast should be. I had a hard time finding a solid ground so I cheated and pulled it from the headlight socket. I converted to an LED so I know the draw on the circuit won't be taxed by the extra load from the horn relay (someone with actual electrical engineering knowledge here please correct me if I'm off base or messing things by cross-feeding the electrical system)

20161106_125044

20161106_125044 by

Ethestral, on Flickr

top left to right

Headlight socket, tapped for solid ground. Relay supporting the far end of the compressor (low left). Compressor is the cylinder mounted in the middle (drilled one hole in the lower headlight support to mount). Far right, blocking the view of the fork tube is the horn unit.

All buttoned up left side

20161106_143155

20161106_143155 by

Ethestral, on Flickr

All buttoned up right side

20161106_143215

20161106_143215 by

Ethestral, on Flickr

In case you didn't see the wiki from Semper Why on how to tap the fusebox before it hits the factory fuses you can read it here

http://zeromanual.com/index.php/Common_Modifications#New_CircuitsIts solid, yes the pro tip is to remove the 3mm screw most inboard on the bike and pivot the block down to spring the plug from the top. I double checked on my bike to see that the feed to the fuse block came from the top not the bottom of the block.

20161030_154238

20161030_154238 by

Ethestral, on Flickr

This is where I pulled my hot to feed the relay, I do worry a little that I will over load the 14ga wire feeding this single fuse. However I see a horn blast as a momentary event. On my build that circuit is only feeding a two amp USB charger, and the fuse on the horn lead that I added is a 10amp. I am only overrunning the designed load by 20% on a momentary basis. If I add heated gear I will need to reconsider my voltage feed, stumble deeper into the depths of the black box on my go fast machine.

Author

Topic: Air horn on the DSR 2016 (Read 2702 times)

Author

Topic: Air horn on the DSR 2016 (Read 2702 times)