I got the Domino throttle onto the MX last week. I like it! The quicker action makes it a little easier to both accelerate & brake, with less arm pump. It feels a bit faster too, which is surely my imagination.

These were kinda hard to find for a while, but EVDrives and Electric Motorsport have them in stock again, as of a few weeks ago anyway. I got one each of the IP54 (water-resistant) and IP67 (waterproof to 3m) units, which are identical except for pots and feel exactly the same when turned; I used the IP67. The Domino has about 78° or so of rotation - it's hard to measure exactly, but the Magura is 90° - along with a slightly smoother feel and longer throttle tube. With a little finessing it fit flush against the kill/mode switch with the tube & bar ends even. It's more crowded than I'd like, but at least I don't have to move the switch to the LH side (yet).

Magura (top) & Domino:

The OEM Magura cable is 23.5" long to reach the harness connector above the F battery bay, but the Domino's was only 15" which barely reached my key switch.

The easiest way to make it work is by adding an extender cable to the large 5-pin connector that comes with the new throttle, but I didn't want the extra set of contacts or microswitch connections so I replaced the entire cable. If you're planning on using the microswitch, you may want to go a different route.

Here's a before & after shot:

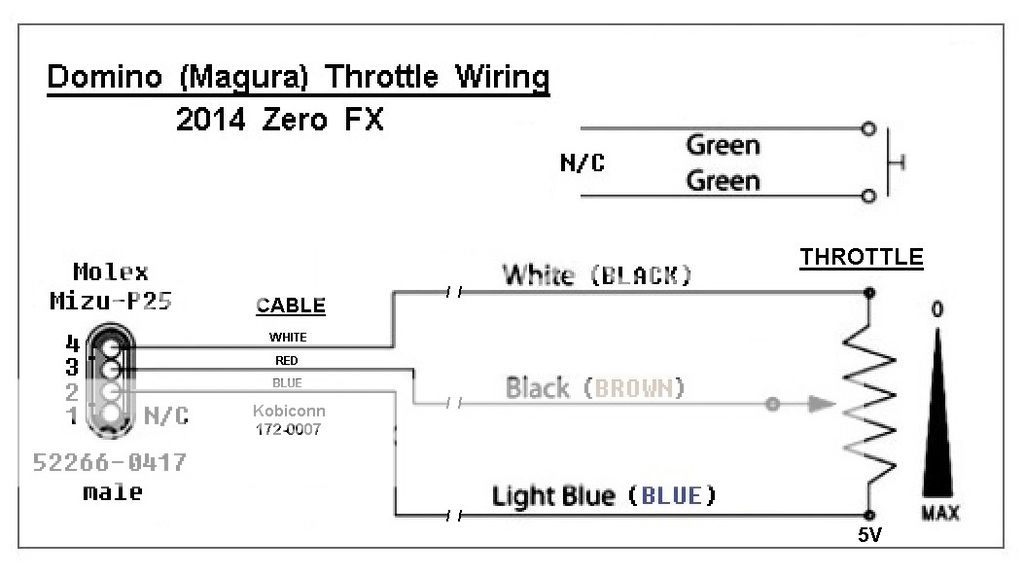

To mate the Domino's 5k pot to the '14 FX harness throttle connector the following items are required (I used Mouser Electronics for convenience):

Molex 'Mizu-P25' 4-pin male connector (Molex P/N 52266-0417)

3 male terminals for above (50147-8100)

extra cable (I used a Kobiconn P/N 172-0007 DIN cable, which worked great)

T10 Torx driver for Domino cable cover (had this already)

I also got these for testing, which came in real handy:

Mizu-P25 4-pin female connector (52213-0417)

3 female terminals for above (50148-8100)

I did the female first with some short pigtails as a practice run, which turned out to be a very good idea.

If you're experienced with small crimp terminals and thin wire it should be relatively easy, but it had been years since I'd done anything similar and it could've gone smoother at first.

Here's the wiring I used (see diagram below - ignore Magura wire colors in parentheses):

Domino white ("0V") wire to cable white wire / connector pin 4

Domino black (pot wiper) to cable red / pin 3

Domino blue (5V) to cable blue / pin 2

Here's what I did, in excessive detail:

1) Starting with the already-stripped end of the Kobiconn cable, I cut the wires to @ 20mm long, stripped 3mm of insulation off the red / white / blue wire ends (26 AWG), snipped off the braid & unused yellow wire, then pre-tinned the copper.

2) Slip the Molex water seal & snap-on cap onto the wire ends, with the large flange end of seal & cap snap protrusions facing the tinned ends.

3) Crimp & solder the terminals onto the wires. The outermost (wire side) terminal crimp ears grab the wire insulation, not the conductor. These must be carefully wound around the insulation for minimum O.D. and then crimped, or they may snag on the connector's terminal tunnel during insertion. The inner contact-side crimp ears grab only the conductor. These are shorter and can be 'squashed' straight across L to R without insertion-clearance issues. Try to use the minimum amount of solder and heat, as the thin metal can warp & excess solder can wick up to the terminal contact and ruin it.

4) Make sure the terminals are oriented correctly before insertion; these are flimsy little things that lock in position, and you may only get one shot at it. Both male and female terminals should be inserted into the connectors so that the formerly-open (now crimped) ends of the crimp ears are facing the side of the connector with the '1' pin-1 raised mark (see photo below of male connector's cable side, '1' is on top, uncrimped terminal properly oriented in unused #1 pin position). Molex calls them "low insertion force", which is true only if the crimping/soldering is done correctly and the terminals haven't deformed from the heat.

5) Once all three terminals have clicked into position (leave the pin 1 position empty, as Zero uses a sealing pin in the female harness connector), snap the seal & cap into the connector body.

6) I cut the cable to @ 26", stripped @ 20mm of outer jacket & 10mm insulation off the R / W / B wire ends, braid & yellow wire off, then pre-tinned the copper again.

7) Back to the connector end - I coated the cable-jacket end / wires / connector's wire side with Liquid Tape electrical sealant, then put heat shrink over all of it. This appears to be what Zero did with the OEM Magura connector, and I've read far too much here re water-related problems to screw around.

8 ) At the throttle, I removed the cable cover & cut off the green microswitch wires at @ 20mm long, then tucked them back into their cavity in case I needed them later (as mentioned earlier, you may want to do something different). I cut all 3 pot wires at @ 20mm, then stripped / tinned / twisted them to the cable wires, soldered them, trimmed them down, & Liquid Taped / heatshrinked them individually, with the heatshrink holding the spliced ends tightly together. There's not much room in there, so keep things as short as possible.

9) Finally, I tie-wrapped the cable end to the throttle body as done originally (visible in pics 1 & 4 above), slid the cover back on (it's tight on the cable, be careful) & screwed it back onto the throttle, then lubed the tube I.D. only with liquid PTFE/Teflon and slid it onto the dry bar end.

If Domino had spec'd a 24" cable, this process would've been

so much easier.

Gratuitous bike selfie:

Ray

Author

Topic: Domino Throttle Installation (Read 10094 times)

Author

Topic: Domino Throttle Installation (Read 10094 times)